EyeVision Software

Our most versatile product optimally tailored to your needs

One-dimensional image processing is the simplest but one of the most widespread forms of image processing. As a rule, so-called line scan cameras are used for web inspections where the objects to be inspected are constantly in motion. Line scan cameras can identify, classify and count objects.

Common applications are:

- the inspection of continuous materials such as films, paper or textiles for specks, thin spots, tears, holes, discolouration, dirt, tension or bubbles.

Woven material for e.g. weaving defects - Large components such as boards, metal struts, foams, etc

- Reading 1D barcodes (GS1, UPC, EAN, Code 128 etc.) in retail, for consumer goods or in logistics.

- Counting objects on conveyor belts.

Line scan

Barcodes

Packaging scan

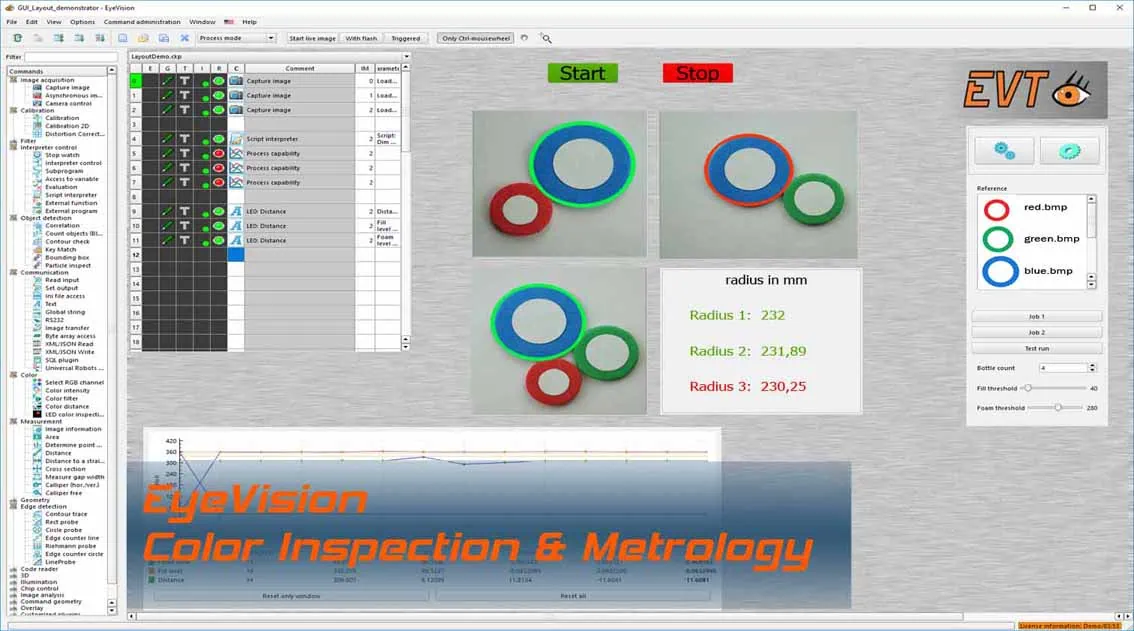

Two-dimensional vision solutions are currently the default setting for most vision applications and capture standard 2D images of objects, which are very suitable for inspecting individual items and scanning barcodes. Area scan cameras have rectangular image sensors that capture images in a single frame, with the resulting image corresponding to the height and width of the image sensor.

Common applications are:

- modern barcodes on consumer goods such as food, electronic devices, etc.

- Measurement of parts and materials

- Differentiating colors

- Inspection of small parts such as screws

Bottle inspection (lid, screw cap, label, fill level)

Wire color inspection

Measurement of production parts

gear wheel inspection

2D Barcodes OCR

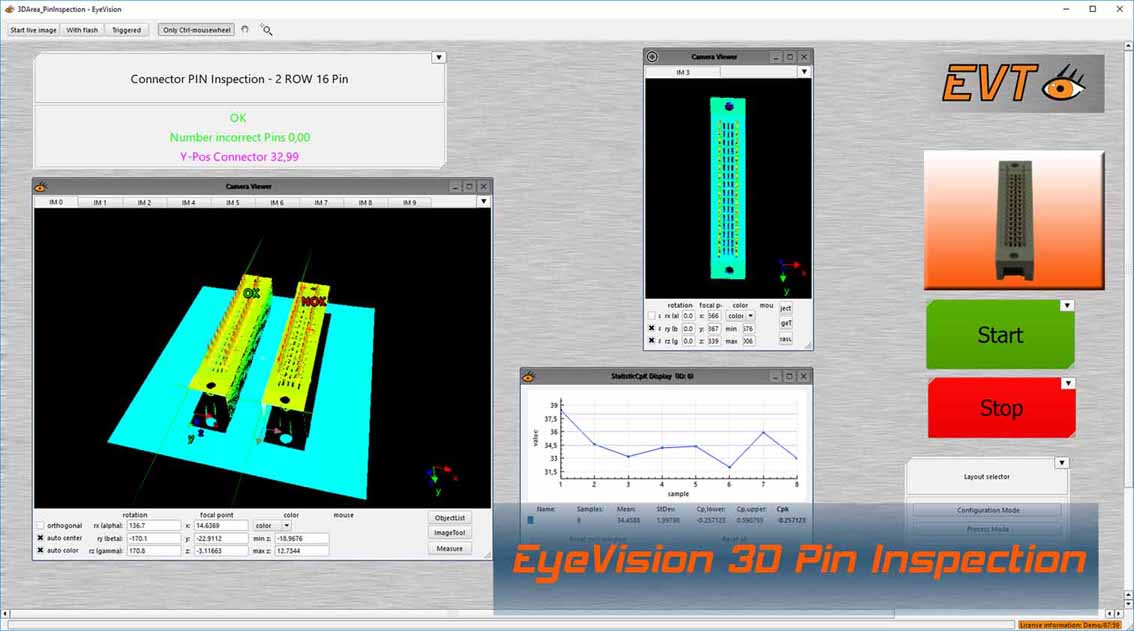

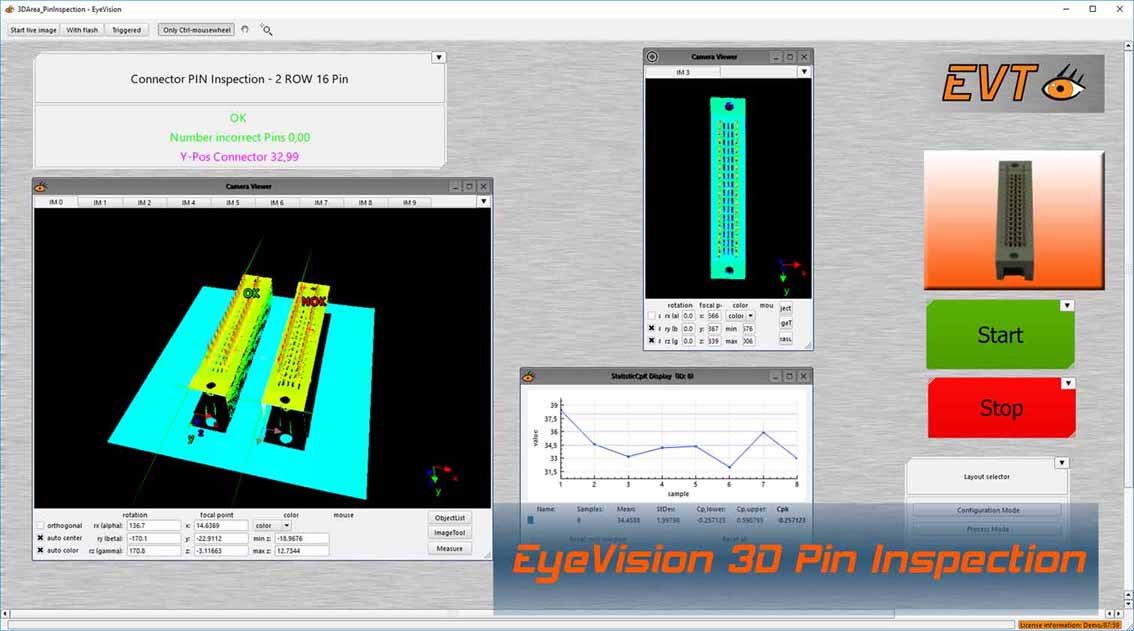

The key function of the EyeVision 3D software is the acquisition and use of 3D images (point clouds).

Based on the point cloud, EyeVision 3D has various commands:

- recognise and count objects

- find defects

- Perform various metrology operations

EyeScan 3D sensors for the EyeVision 3D software

EVT opens up the third dimension for users with the EyeScan 3D camera system.

- Surface inspection also with machine learning algorithms

- 3D acquisition and evaluation on the point cloud for e.g. pin inspection, bin picking, etc.

- 3D profile measurement for e.g. weld seam, adhesive and sealing bead inspection

3D sensors can be used in all industries, e.g:

- for quality inspection

- for controlling robots

- for µ-precise measurement technology

EyeScan 3D means for the user

- a fully calibrated 3D sensor – based on laser triangulation or surface measurement

- The entire EyeVision 3D evaluation software is already included in the system and is programmed by drag-and-drop.

Here are some examples of how EyeVision 3D

- for the optimisation of production processes

- to improve quality control and

- to reduce manufacturing costs

Automotive

A 100% quality control is essential for tyre production. A 3D inspection also detects the black imprint on a black tyre. At the same time, other surface defects can also be recognised.

Car gap size

EyeVision 3D checks different gap types, such as: simple gap, projection gap, gap with bottom, advanced gap types, …

Breakfast Roll Check

3D point clouds scan

Electronics

Circuit boards

For testing soldering processes and components for: Alignment, position and presence

Smarthphone

For checking small-format substrates, e.g. smartphone glass. Can measure rigid components as well as the transmission of filter layers on glass substrates.

Sealing

Sealing

EyeVision 3D checks whether the sealant has been applied correctly and also checks the placement of the sealing material. EyeVision and the EyeScan 3D sensor guide the robot.

Weld seam

Checks seam width and length, missing seam, crater-free design, seam penetration, seam bonding, uneven leg, as well as holes & surface pores

Glue

Non-contact and non-destructive testing directly after adhesive application. Suitable for all adhesives & surfaces. EyeVision 3D recognises defects such as: Interruptions, thickenings and irregularities in adhesive beads.

Bin picking

Bin picking

EyeVision 3D detects components in any position and rotational orientation and reacts to changes in the position of the objects. EyeVision 3D enables full utilisation of the robot line and saves space.

Other applications

Area Scan

EyeVision 3D can record large surfaces with the 3D unrolling command and reproduce them undistorted without the need for an axis or a robot.

Consumer goods

EyeVision 3D checks for shape defects, such as: Cylindricity, waviness, circularity. And checks geometric features such as: Diameter, height, width, etc.

Metall casting

The 3D sensor captures finished metal castings and compares the scanned image with the CAD data. EyeVision 3D checks the shape and dimensions during the production process.

Food

EyeVision 3D captures 3D data on the size and shape of fruit, for example. The fruit can then be sorted. This process prevents rejects.

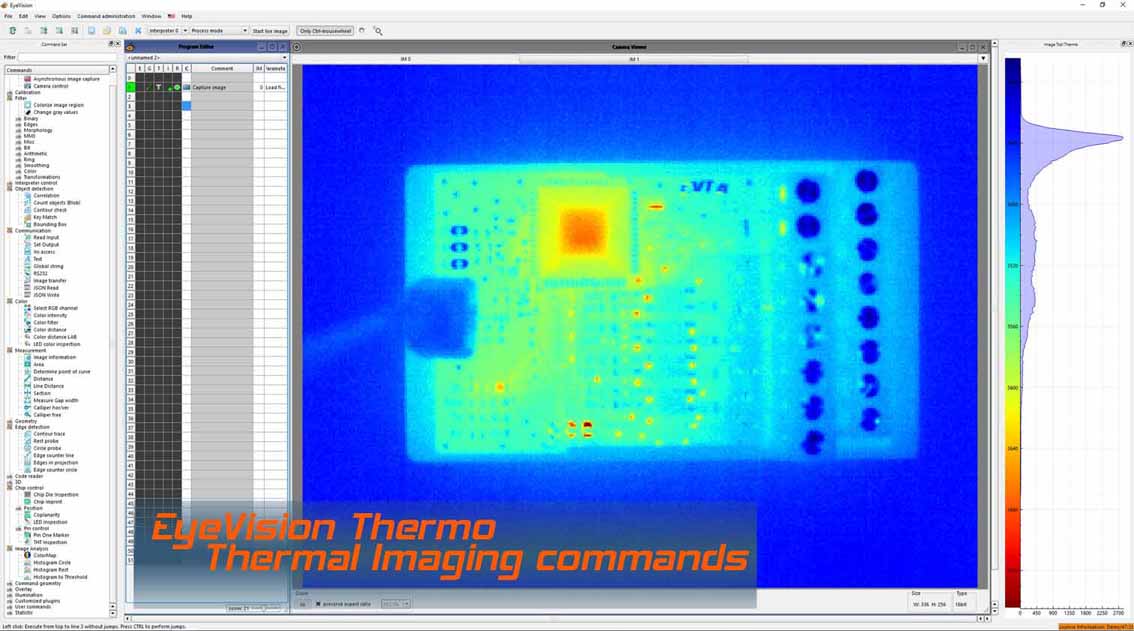

EyeVision Thermo uses infrared radiation to visualise temperature differences in surfaces. This allows information that is not visible to the human eye to be captured and defects to be recognised.

Thermographic image processing is used for quality assurance, e.g:

- Thermography acquisition and evaluation with special commands (active, passive and lock-in thermography)

- Temperature measurement

- Weld seam detection

- Glue spot detection

- Temperature distribution in thermoforming processes

- Inspection of fibre composites

- Electrical component testing

- Testing of precision resistors

- Leakage testing, packaging inspection

- Inspection of sealing seams, sealing and plastic welding processes

- Troubleshooting in the area of high and low voltage

- pipework insulation

- Refractory lining of furnaces

- Optimisation of casting moulds

- Fill level detection of containers

Hot glue inspection

Thermo tracking

PV inspection

Hyperspectral imaging is a technique that collects and processes information about the entire electromagnetic spectrum to obtain the spectrum for each pixel in an image. It contains all types of light, from very long waves (radio waves) to very short waves (gamma rays), most of which are imperceptible to the human eye. This enables the identification of objects and materials by analysing their unique spectral signatures.

With EyeVision Hyperspectral it is therefore possible to identify quality defects of objects that are unrecognisable to the human eye, such as

- Inspection and classification of food, non-destructive detection of contaminants and defects in industrial products such as mould or unripe fruit and vegetables.

- Analysis and visualisation of material compositions

- Recognising and differentiating materials, e.g. rubber parts in tobacco

- Sorting and recycling waste according to purity level

- Control in pharmaceutical production

apple scan

The EyeVision Deep Learning software constantly improves its capabilities by practising with lots of data, this is known as training. It is a type of machine learning that uses artificial brain cells called neurons. These neurons are arranged in layers and neurons in one layer can communicate with neurons in the next layer.

The layers are organised as follows:

Input layer: The input layer receives the raw data, e.g. the pixel values of an image.

Hidden layers: These intermediate layers perform transformations on the input data and extract features and patterns.

Output layer: The output layer produces the final prediction or classification, e.g. the identification of objects in an image.

- The algorithms can be integrated into any image processing software.

- The tool can be used in any ROI that uses, for example, the size of the deviation as a quality criterion for the surface defect.

- No pre-learning

- No need to set parameters

the algorithm automatically adapts itself to any remaining surface - Evaluation of the inspected surface in less than 50 ms on Core i3

- Can be used in areas such as Surface recognition

Bin Picking

EyeVision Robot enables machines to understand and interpret visual information from their environment using deep learning.

Techniques such as image enhancement, restoration and segmentation are used to extract useful information from images, while advanced perception techniques such as object recognition, face recognition and scene understanding enable robots to understand and navigate their environment. Control techniques such as image-based control and visual pathfinding allow robots to manipulate objects and move precisely in space.

Possible applications include

- Logistics and production, where robots equipped with image processing can perform tasks such as identifying, picking and placing products with high accuracy and efficiency.

- In medicine for image-guided surgery, where robots equipped with image processing can assist surgeons in performing operations with greater precision and accuracy

- Therapy robots, such as exoskeletons, to assist patients with mobility problems.

In the areas of surveillance and security, such as security cameras or drones.

Robot calibration

Bin picking

Real time tracking

Try out the demo Version of EyeVision Software completly free! If you need any help or inspiriation Contact us or look at our Demo Videos.

After you are convinced simply send us your used commands and required functions with the automatically generated license file and we will configure the software package for you with the functions that you need

Further information about the software

EyeVision is synonymous for “zero-error-production”, a reduction of production time, for quality and production acceleration and therefore als for a higher customer satisfaction.

Thanks to fast installation and univeral usage, the software creates a fast, efficient and cost-effective solution for all applications.

The packages contain different command sets. But the extendibility of the EyeVision software are unlimited:

You can add any command any time to any package.

Additionally, there are special command sets such as:

- ChipControl (for the semiconductor industry)

- Commands for color inspection

- Code Reader commands

Those can also be added to each package. Individually, depending on application and demand.

Drag-and-drop programming

The software is flexible and easy to handle. EyeVision is programmed via the graphical user interface (GUI). The easy programming via drag-and-drop is a well-known feature of the image processing software.

The intuitive user interface allows the creation and configuration of new inspection processes very easy and fast. Thanks to the innovative technique the handling is even for less experienced user very easy.

Flexible hardware choice

EyeVision supports line scan, matrix, color, gray scale, thermal imaging and 3D sensors with following interfaces:

- USB 2.0, 3.0

- GigE

- GenICam compatible cameras

- FireWire

- Camera Link

- RS232

- CoaXPress

The image processing software runs on ARM, x86, x64 and MIPS.

Image processing software for the Smart Camera

Additionally, the EyeVision is also available on the smart camera series EyeCheck and the vision sensor series EyeSens.

MIPI Software EyeVision

MIPI CSI-2 is already an important interface for mobile devices like smart phones or tablets, but also in image processing and many Embedded Vision applications it plays an important role.

EyeVision supports MIPI sensors by Allied Vision Technology, Basler, Vision Components and Raspberry Pi. This is a list which will grow even longer.

For the implementation of an embedded vision solution with MIPI sensors, EyeVision supports also the following boards:

Asus® Asus® Tinkerboard (Processor: Rockchip® RK3288) | Auvidea Auvidea NVIDIA® Jetson™ J100 (Processor: NVIDIA® TX1) Auvidea NVIDIA® Jetson™ AGX Xavier™ Carrier |

DragonBoard™ DragonBoard™ 410C (Processor: Snapdragon™ 410E) DragonBoard™ 820C (Processor: Snapdragon™ 820E) | Geniatech 4 IoT – Geniatech (Processor: Snapdragon™ 410E) |

HiKey HiKey960 (Processor: Kirin™ 960) HiKey970 (Processor: Kirin™ 970) | HummingBoard™ HummingBoard™ (Processor: NXP i.MX6) HummingBoardPro™ (Processor: NXP i.MX6) |

MediaTec MediaTec X20 (Processor: Helio X20) | MSC MSC SM2-MB-EP1 (Smarc carrier board) |